K2-Dowel

DOWEL WEEK 2024

Before today's indispensable dowel was invented, a chisel was used to make a hole in the desired location and then a piece of wood was pressed into it, where a screw was then turned in. This method has been a thing of the past for a long time, as a dowel was first industrially manufactured in London in 1910 by the Briton John Joseph Rawlings. The components were a hemp rope and animal blood, which was used as an adhesive. The patent was registered in 1911, laying the foundations for today's fastening system.

Germany followed in 1928: a new patent was granted for the "sleeve expansion plug" in the name of Fritz Axthelm (engineer and co-owner of the Niedax company). The Niedax dowel was initially made of metal and after the Second World War of plastic. Fritz Axthelm is therefore the inventor of the plastic dowel that is widely used today.

MEFA was founded in 1949 by Friedrich Krätzer and has been producing metal dowels since 1950. In 1956, the metal and fiber dowel known to this day was introduced and in 1962 the innovative plastic dowel "Nylon dowel K2" was developed. This was the inspiration for our current company name: METALL FASERSTOFF DÜBEL (Metal fiber dowel)

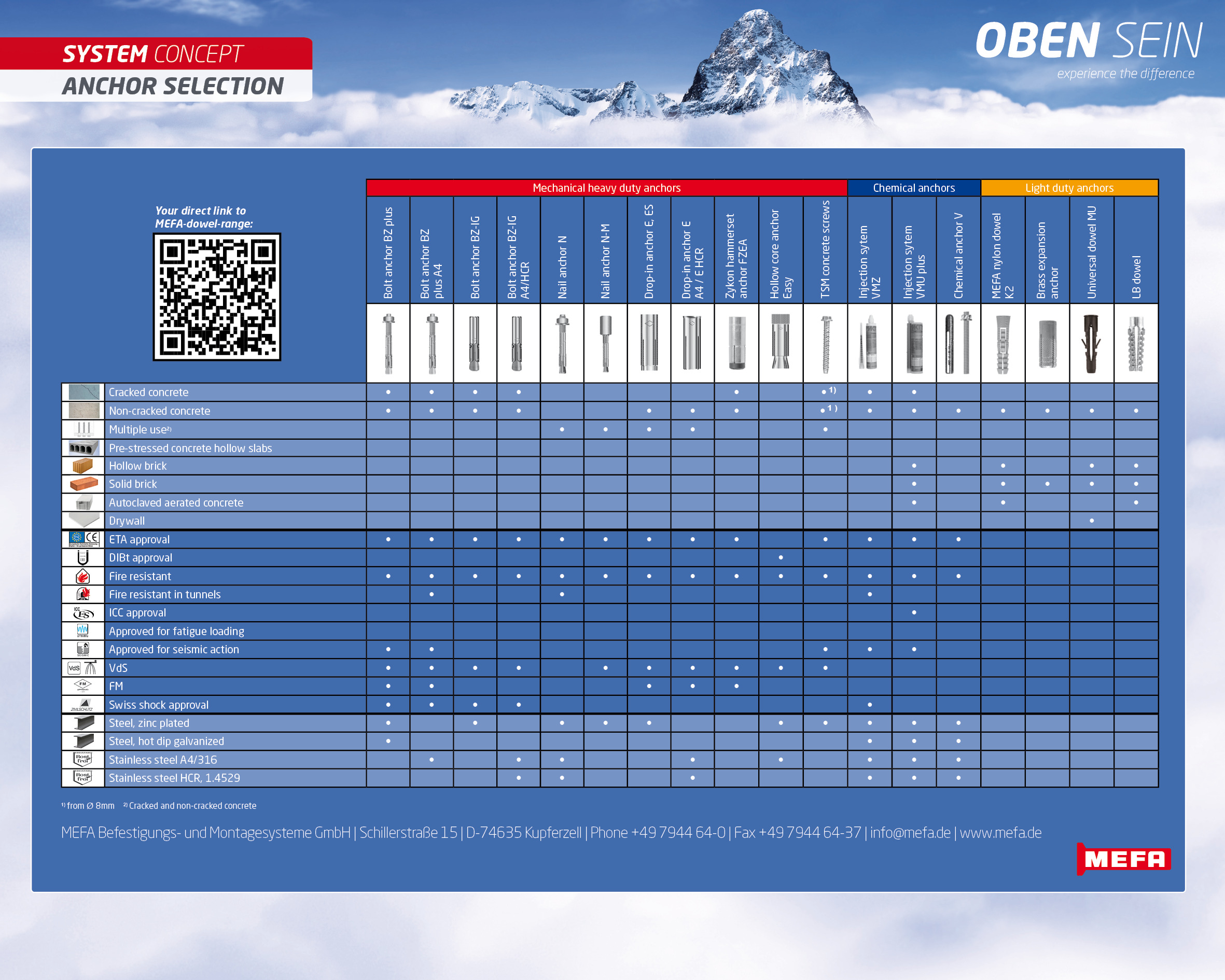

The dowel is a component that is taken for granted and is actually so much more complex than it appears at first glance. The variety of different dowels for different materials is indispensable these days. Basically, dowels are a component required in fastening systems, that is used to anchor attachments in floors, walls or ceilings. Our range at MEFA includes plastic, metal and chemical dowels.

The plastic dowel is ideal for low loads. Plastic or nylon plugs are generally used in the home, for example. The classic: The plastic expansion plug, also known as the standard plug or universal plug, is considered the all-purpose weapon among plugs. It is particularly popular as it is suitable for concrete, perforated and solid stone, masonry, plaster, wood and natural stone. The K2 is the right choice from our range for lightweight fastenings.

Metal dowels, usually also known as metal anchors, are used for high loads. This type of anchor is available as hollow core anchor, expansion anchors and screw anchors. A well-known example is the drop-in anchor: this is particularly suitable for heavy loads and cracked and non-cracked concrete. It expands in order to hook into the substrate, but it is not screwed in but driven into the wall with a special tool.

Anchor systems with approval for individual fixings are required for fixing heavy attachments or load-bearing structures in concrete or masonry. Typical heavy-duty fixings include railings, brackets, beam connections, steel beams or metal structures. Heavy-duty dowels are used wherever plastic dowels and other subordinate fasteners can no longer be used or do not have the appropriate approval. The heavy-duty anchor, a special form of metal anchor, is used for the most demanding tasks and can be an expansion anchor, undercut anchor or composite anchor. The possible load ranges from a few hundred kilograms to several tons - depending on the exact type of dowel, size and load-bearing capacity of the substrate. There are different metal anchors for different applications in our eShop. From bolt anchors to drop-in anchors, we have everything you need for heavy-duty mechanical anchors!

The third variant in our range is chemical anchors, for example injection systems and bonded anchor systems. They differ from metal and plastic anchors in that they consist of three components: the sieve sleeve, the threaded rod and the synthetic resin mortar, whereby a sieve sleeve is only required for cavities. When using a chemical anchor, the sieve sleeve is first pushed into the drill hole, if necessary. Synthetic resin mortar/two-component mortar is then filled into the drill hole and the sieve sleeve. The mortar is partially absorbed into the pores of the masonry and at the end the Anchor rod is inserted and aligned. After around an hour, the mortar hardens and a stable connection is created.

K2-Dowel

Bolt-anchor BZ plus

Injection System VMU plus

All the dowels in our range at a glance, including approval, material and area of application.