Visually appealing, easy to install and designed for high tensile loads

27 June 2023 , MEFA Blog-Team

Ventilation ducts are often used purposefully as an architectural element. This trend will gain more popularity because higher demands come with larger and additional ventilation systems. Since technical rooms and supply shafts are measured narrowly, there is only a way out into the visible area. Most affected are buildings like schools, sports facilities, hospitals, and event rooms. In this context, it is reasonable to use the ventilation technology as an artistic element with demands on aesthetics.

Rectangular ducts and round tubes are the most common duct types. In comparison, each of their advantages and disadvantages: The height and width of rectangular ducts can be chosen freely. This reduces building costs since it can spare building height.

But flange joints, used in rectangular ducts, eliminate the advantage of building heights. But there is another disadvantage: Within the ducts, dirt and dust can gather in the corners since they are poorly ventilated. This creates a habitat for unwanted small creatures. Cleaning them with brushes is nearly impossible. (More about the installation of rectangular ducts can be found here)

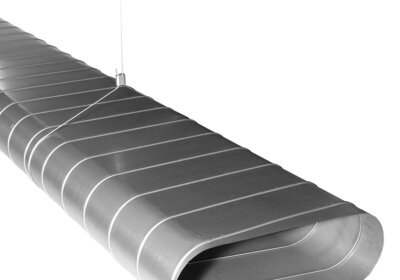

This is not the case with round ducts; they are aerated well and easy to clean, so they are suitable for sanitation sectors. Also, regarding architecture, there are numerous examples of the design of round tubes in visible areas. A particular form of ventilation pipelines are oval tubes. It saves space through a low building height without flange joints and is often used in confined spaces.

Photos: many thanks to m & a Luftleitungstechnik for providing the photos.

If a ventilation pipe or oval pipe is used for ventilation systems, it is, at first glance, just a distinctive feature. But a closer inspection reveals small, but fine, technical differences. Within ventilation technology, oval tubes combine the advantages of round tubes and rectangular ducts.

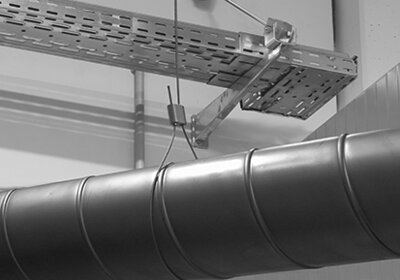

Our wire rope L-Fix is suitable for hanging oval or coil-folded pipes, which we offer as a supplement to the “conventional” fastening technology (ducting straps, trapeze hangers, and ventilation pipe clamps).

The rope system is an optically very appealing and filigree fastening solution that can be mounted easily and quickly. The central element of the rope system is the L-Fix lock, with an oval cross-section and two passages for steel ropes. In each of the passages, there is a clamping device that works according to the principle of self-locking and holds the rope securely. During assembly, the rope, available in diameters of 1.5 mm and 2.5 mm, must be inserted into one of the two clamps of the lock in the direction of the arrow to loop the pipe and push it upwards through the second clamp. The connection can be easily released by pressing the cable clamp. This allows fitters to install and correct the pipe suspension in just a few seconds, even without tools.

The L-Fix connector axial (M8) is infinitely adjustable for threads or through holes such as mounting rails with Stex GP, threaded and toothed plates, duct holders, or device connections. With the L-Fix thread, it produces an "adjustable threaded rod".

The L-Fix connector tangential is used for fixing in surfaces with M8 connections, such as drop-in anchors and pipe clamps with step threads. Clever: The tangential connector allows variable height adjustment even if the rope cannot be guided "through" the ground. This feature pays off particularly in sloped ceilings. Both connectors have a cable diameter of 1.5 mm up to a tensile load of max. 0.32 kN, or 2.5 mm up to max. 0,82 kN. As an accessory, there are special pliers for lengthening the steel ropes, which reliably prevent the splitting of the rope ends.